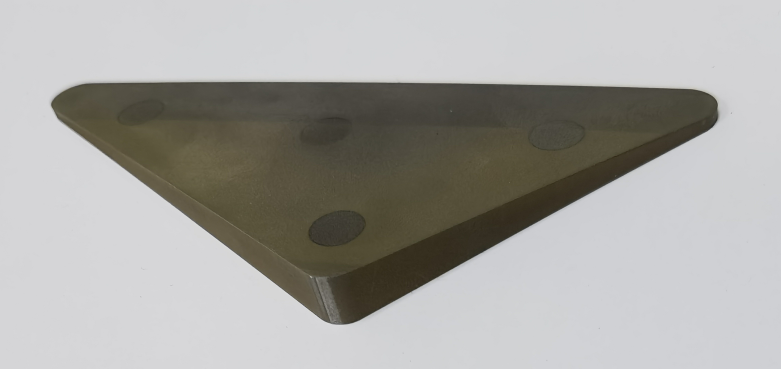

《Tungsten steel products》

A. Material:Tungsten steel refers to WC and CC powder as the main raw materials. The alloy material obtained by powder metallurgy method, series of processing technology mixing, pressing, and sintering. It has the characteristics of high hardness, high strength, corrosion resistance, stainless steel, etc. It is widely used in the production of high wear-resistant parts in hardware, machinery, chemical and national defense industries.

B. Difficulty. Craftsmanship and solutions:

The material of this product is WC/CC tungsten steel. Hardness can reach 89/95HRA. The surface requires a smoothness of 0.4. Precision size.《Shape angle. Easy to jump edge.》Shape. Outer diameter. Inner diameter. Fine hole. Tooth hole. Step. Bevel. Square groove. U-shaped groove. Transition R......

Process: ① Internal and external finish requirements are 0.4. The roughing process must be opened, and the unilateral margin is within 0.2/0.25. ②This kind of product is easy to jump because of tungsten steel. Look for special gold steel blades or diamond grinding wheels for processing. The blade roughing can choose 0.2/0.3R angle . Select 0.1R for finishing. 《For sharp corners, choose tight cart or reverse machining. Not easy to jump corners》.《80 molybdenum can be selected for coarse gold steel grinding wheel. Fine grinding 0.4 finish. 320 molybdenum or 400 molybdenum can be selected.》 ④Inner hole. Inner groove. Straight groove. 《Optional piercing machine first pierces the bottom hole. Then it is processed at a slow speed. The finish and tolerance dimensions can be reached.》 ⑤Slope. Step. Over R. Tooth hole 《According to the requirements of the drawings. Made of copper. Thick. Thin can generate sparks or mirror sparks. The finish can reach within 0.4. 》

C. Processing products. Equipment and tools cut into

1. Wire cutting: perforator.《Fast wire. Middle wire. Slow wire》

2. Grinding machine: Diamond grinding wheel.《Surface Grinding. Centerless Grinding. Internal Grinding. External Grinding. Punch Grinding. CNC Grinding》

3. Electric spark: Tong Gong 《Ordinary EDM. Mirror EDM》

4. Welding: 《Brazing. Silver soldering》

Note: The tungsten steel material is made of high-quality WC/CC tungsten steel. The hardness can reach 89/95HRA. Because of the extremely high hardness of tungsten steel, it is brittle. It is easily broken by external impact. Especially the thickness of the tungsten steel slitting blade is thin. It is easy to break when punched by external force. When installing and using various tungsten steel materials, knocking, throwing, etc. are prohibited. The edges of the materials are extremely sharp. Please pay special attention to safety during installation to avoid unnecessary personal injury. Products made of tungsten steel The parts are particularly wear-resistant. The life span is more than ten times that of high-speed steel "white steel". It can greatly improve your work efficiency and reduce your costs.